● Industrial Heating & Ventilation

First and foremost, pipe insulation is a fundamental part of reducing heat loss and energy costs. This applies to both domestic and industrial application, and also plays an important role in protecting the environment

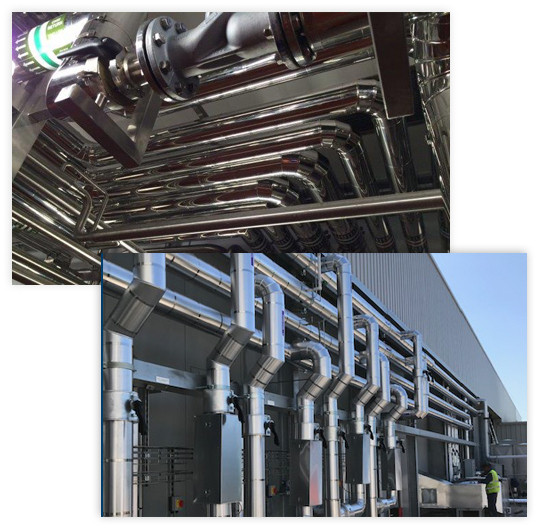

● Food Processing

A key sector in which pipe insulation is used is in food processing. Insulating food processing equipment can be a difficult task. There is a high risk of product contamination, therefore any insulation in production areas will be subject to specific risk assessments and method statements.

● Breweries

Insulation in a brewery is a crucial step in precisely controlling each step of the brewery process.

● Refrigeration

Insulation of low temperature refrigeration pipework and equipment is a very specialized type of work. This type of work requires a multi layered insulation system to suit each customers requirements.

● Hospitals

● Pharmaceutical

We use a wide range of materials across our insulation products:

● Mineral Wool

● Phenolic Foam

● PIR

● Foam Glass

● Armaflex / Nitrile

● Calcium Silicate

● Thermal Ceramics

There are a wide variety of different options for high quality coverings and finishes for pipe insulation. Here is a brief breakdown of some of our favourite options:

● Aluminium Cladding

● Aluzinc Cladding

● Stainless Steel cladding

● PIB Weatherproof sheeting

● Isogenopak

● Venture Clad

● Plastisol (various colours)

Heat conservation is required for pipes running at high temperatures to ensure minimum heat loss from the service. This can provide significant energy savings by reducing heat flow from the pipe to the outside air.

This naturally also has benefits for the environment, in that less heat needs to be produced, leading to less CO2 emissions.

Some services require insulation for personal protection, to enable employees to work alongside essential services in a safe manner. This is due to the risk of operatives burning themselves on high temperature plant and equipment.

Many water pipes are located in areas where there is no heating and as a result, the temperature can fall below freezing point. When the water then expands as a result of the freezing, the pipe system is usually broken or blocked.

Therefore, pipe insulation and trace heating can play an important role in helping to prevent the water from reaching such a low temperature in the first place.

It is important to maintain the desired temperatures in your pipes to ensure the liquids are constantly moving along. Pipe insulation is key when it comes to temperature control.

Many essential services need low temperature refrigeration pipework to have the necessary low temperatures in the pipes at all times without causing any problems such as freezing. This requires a specialised insulation to prevent any ice build up throughout your pipework.

Chilled & cold water services require pipe insulation for many reasons, especially for preventing condensation, as this causes dripping from pipes which is highly undesirable and can lead to many safety hazards.

Specialised insulation can be used to effectively reduce sound transmission through pipework and associated plant and equipment. Some areas require the noise levels to be lowered to meet health and safety levels, therefore this is classed as critical works.